Blogs

Sodiceram: The Next-Gen Sodium-Infused Ceramic Revolution

Published

3 months agoon

By

Admin

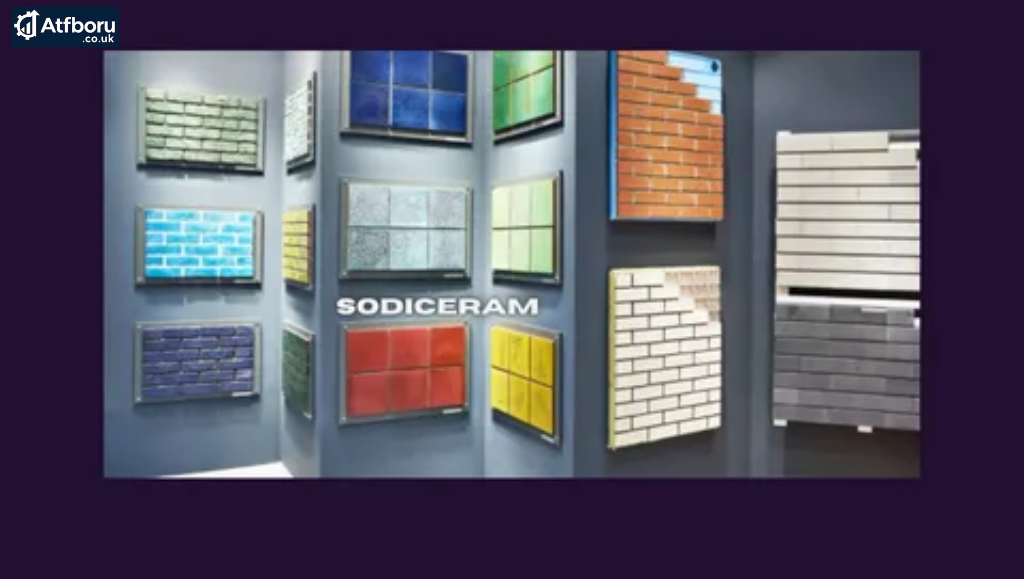

In the world of advanced materials, the demand for high-performance ceramics has led to the development of innovative solutions. One such solution is Sodiceram, a next-generation sodium-infused ceramic that is reshaping the way architects, designers, and engineers approach durability, design versatility, and performance.

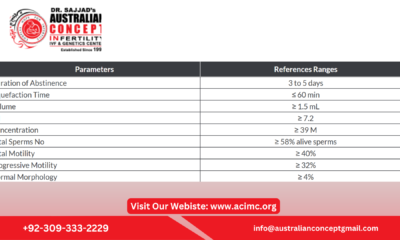

Unlike traditional ceramics, Sodiceram integrates sodium-based compounds like sodium feldspar and sodium carbonate (Na₂CO₃) into the ceramic matrix to offer superior characteristics such as low porosity, higher flexural strength, and improved thermal shock resistance. This article explores the emergence of Sodiceram, its unique material properties, applications, and its position within the broader ceramic market.

What is Sodiceram and How Did the Concept Emerge?

Sodiceram is a cutting-edge ceramic manufacturing material infused with sodium-based compounds, particularly sodium feldspar. This infusion enhances the material’s vitrification process, reduces porosity, and improves both mechanical strength and thermal resistance. Unlike conventional ceramic or porcelain materials that rely on kaolin clay and feldspar for vitrification, Sodiceram achieves superior performance through sodium’s unique role as a flux agent.

The concept of Sodiceram emerged from a convergence of advanced ceramic engineering and the growing demand for more durable and versatile materials in architectural and industrial applications. Researchers recognized the potential of sodium to facilitate controlled vitrification at lower temperatures, which led to the development of Sodiceram. Over time, breakthroughs in sodium-based compound integration paved the way for its commercialization in applications ranging from flooring to ceramic cladding, countertops, and beyond.

What Unique Material Science Principles Underpin Sodiceram?

At the core of Sodiceram‘s innovation is its reliance on sodium-based compounds to enhance the ceramic matrix. Sodium acts as a flux, lowering the melting temperature of silica and alumina, and improving the densification process during firing. This enables Sodiceram to achieve superior glass-phase formation, which reduces porosity and enhances structural cohesion.

Key material science principles behind Sodiceram include:

- Fluxing Agents: Sodium facilitates liquid-phase sintering, reducing energy consumption and promoting tighter grain packing at lower firing temperatures.

- Glass-Ceramic Formation: Sodium promotes the formation of a glassy phase that envelops crystalline grains, resulting in a denser, more durable product.

- Thermal Expansion Control: The careful balance of sodium content helps in controlling thermal expansion, ensuring that Sodiceram performs well under varying temperature conditions.

What Are the Key Performance Advantages of Sodiceram?

Sodiceram offers a range of performance advantages that make it superior to traditional ceramics:

- Low Porosity: Sodiceram achieves porosity levels as low as 0.5%, significantly improving stain resistance, water resistance, freeze-thaw durability, and chemical exposure resistance.

- High Strength: With a flexural strength surpassing 40 MPa, Sodiceram exceeds the typical range for porcelain and other conventional ceramics, making it ideal for high-traffic environments.

- Thermal Shock Resistance: Sodiceram can withstand sudden temperature changes of up to 200°C without cracking, making it suitable for applications such as kitchens and laboratories.

- Chemical Resistance: Unlike standard ceramics, Sodiceram resists acids, alkalis, and household chemicals without degradation, making it an excellent choice for industrial ceramics and corrosive environments.

In Which Applications Does Sodiceram Shine?

Sodiceram‘s unique properties make it suitable for a variety of applications:

- Residential Spaces: From kitchen countertops to bathroom cladding, Sodiceram‘s aesthetic versatility and durability make it an ideal choice for homes. Its resistance to staining and scratching is especially beneficial in high-use areas like kitchens.

- Commercial Settings: Airports, hospitals, and shopping centers benefit from Sodiceram’s ability to withstand high foot traffic, chemicals, and thermal shock resistance. It is also used in industrial facilities such as laboratories and cleanrooms.

- Architectural Façades: Sodiceram‘s UV stability and low maintenance make it perfect for high-rise cladding and ventilated façades, offering both durability and aesthetic appeal.

How to Specify, Design, and Install Sodiceram Surfaces?

When specifying Sodiceram, architects and designers should consider factors such as finish, color, thickness, and mechanical strength. The installation process is crucial to ensure Sodiceram performs at its best:

- Preparation: Ensure substrates are flat and stable with sufficient compressive strength.

- Adhesives: Use flexible cementitious adhesives (C2TES1) to accommodate the material’s thermal expansion.

- Quality Checks: Key checks include tile flatness, edge straightness, and adhesive coverage (at least 90% for large-format tiles).

What Does the Cost Structure and Market Look Like for Sodiceram?

The cost of Sodiceram typically ranges from $35 to $70 per square meter, depending on finish and thickness. While it is more expensive than traditional ceramic tiles, Sodiceram offers superior durability and a longer lifespan, making it a cost-effective choice over time. Manufacturers also offer Sodiceram at a 20–30% premium over porcelain, positioning it as a premium material in the market.

What Sustainability and Lifecycle Aspects Should Be Considered?

Sodiceram aligns well with sustainability goals due to its energy efficiency in manufacturing. Sodium fluxing reduces firing temperatures, saving energy and lowering the overall environmental impact. Additionally:

- Recyclability: At the end of its life, Sodiceram can be crushed and reused as aggregate for concrete or road construction.

- Embodied Carbon: The embodied carbon of Sodiceram is significantly lower than that of porcelain, making it a more environmentally friendly option.

What Are the Main Competitors or Alternative Technologies to Sodiceram?

Sodiceram competes with materials like porcelain, sintered stone, and advanced ceramics. While Sodiceram offers a more affordable alternative to sintered stone, it provides comparable durability and resistance to environmental stresses at a lower price point. Additionally, emerging materials like nanoceramics and smart ceramics integrate sensors or self-healing properties, but they come at a higher cost. Sodiceram strikes a balance between affordability and performance, making it a popular choice for many applications.

What Future Innovations and Research Directions Exist for Sodiceram?

The future of Sodiceram looks promising, with research focusing on:

- Smart Surfaces: The integration of sensors and IoT technologies into Sodiceram surfaces could pave the way for applications in smart buildings, such as self-diagnosing façades and temperature-regulating floors.

- Additive Manufacturing (3D Printing): Advances in 3D printing could allow for more intricate designs and customized Sodiceram components, especially in architectural and medical applications.

- Lighter, Thinner Versions: Ongoing research aims to create ultra-thin Sodiceram panels that maintain strength while offering reduced weight for use in modern, lightweight building designs.

What Are the Benefits of Using Sodium-Based Compounds in Ceramics?

The incorporation of sodium-based compounds, such as sodium feldspar and sodium carbonate (Na₂CO₃), provides several benefits:

- Improved Vitrification: Sodium promotes the glass-phase formation, enhancing densification and reducing residual porosity.

- Lower Firing Temperatures: Sodium fluxes lower the firing temperature, reducing energy consumption and enabling more sustainable manufacturing practices.

- Enhanced Durability: Sodium strengthens the ceramic matrix, increasing resistance to wear resistance, thermal shock, and chemical exposure.

Applications of Sodiceram in Various Industries

Sodiceram is versatile enough to be used across several industries:

- Residential and Commercial Construction: Ideal for flooring, countertops, and cladding.

- Industrial Applications: Useful in cleanrooms, laboratories, and food processing plants.

- Artistic and Decorative Uses: Suitable for sculptural applications, digital printing, and customized designs in both commercial and residential settings.

Advantages and Limitations of Sodiceram

Advantages:

- Durability: Superior resistance to mechanical wear, thermal shock, and chemical exposure.

- Aesthetic Flexibility: Available in various surface finishes, including matte, glossy, and custom designs.

- Sustainability: Lower carbon footprint and energy consumption during manufacturing.

Limitations:

- Brittleness: Like all ceramics, Sodiceram can be brittle under high-impact loads or when improperly installed.

- Cost: While more affordable than sintered stone, it is still pricier than conventional ceramics.

Sodiceram vs. Traditional Ceramics: A Detailed Comparison

Sodiceram outperforms traditional ceramics in several areas:

- Porosity: Traditional ceramics typically have higher porosity, which can lead to water absorption and reduced durability. Sodiceram has ultra-low porosity, improving its resistance to moisture, stains, and freezing.

- Strength: With a flexural strength exceeding 40 MPa, Sodiceram is stronger than many traditional ceramics, making it ideal for high-traffic areas.

- Chemical and Thermal Resistance: Sodiceram excels in environments exposed to high temperatures or chemicals, which traditional ceramics may not withstand.

Conclusion: Why Sodiceram Is the Future of Ceramics

Sodiceram represents a significant leap forward in ceramic technology. Incorporating sodium-based compounds, it offers a combination of durability, versatility, and sustainability that is unmatched by traditional ceramics. Whether used in residential, commercial, or industrial applications, Sodiceram is positioned to redefine the future of ceramics, offering superior performance and design freedom that meet the evolving demands of modern architecture and design. With its ongoing innovation, Sodiceram will continue to lead the charge in sustainable, high-performance building materials.

You may like

Blogs

Fast Chargers & Smart Earbuds for Dubai in 2026

Published

1 month agoon

January 13, 2026By

Steven

Life in Dubai is fast. Smartphone requirements are on the high. From early morning to late night, phones must perform continuously, unbothered. Driving on Sheikh Zayed Road, you just can’t afford to have a call drop. But have you ever stopped and thought if your mobile phone accessories are matching the relentless pace of your lifestyle? It is 2026, and the wrong phone accessories are a source of frustration, while the right ones provide you with convenience. The phone accessories Dubai offers are all about appearances, while hiding poor functionality. In the jumble of phone accessories, the balance of overall design and functionality is hard to find. This guide will help you find smart chargers and earphones that are new, reliable, and designed to be used with your phone every day.

Rising Demand for Smartphone Accessories in Dubai

How High Smartphone Usage Is Driving the Accessories Market

Smartphone accessories in Dubai are taking over due to the high demand that has supplemented the high usage of smartphones. Dubai’s extensive transport system where smartphones are used for navigation and for other means. The need for high quality smartphone accessible durable chargers has become essential in everyday life in Dubai in 2026.

Why Phone Chargers and Earphones Will Continue to Dominate Phone Accessories in Dubai in 2026

From Basic Accessories to Lifestyle Essentials

The UAE market has matured. You do not want to simply buy phone accessories that complete a basic function. We want phone accessories Dubai that fit into our lifestyle effortlessly. Which is why phone Technology trends in Dubai have shifted to focus on fast chargers, wireless charging products, and audio products.

How Modern Phone Usage Has Changed Accessories Trends

Due to increased screen time, app usage, and connectivity, phones require more efficient and protective charging. Meanwhile, remote work, video content streaming, and travel have shifted earphones from an occasional accessory to a daily must-have. These trends have driven an increase in demand for mobile accessories in Dubai, especially earphones and phone chargers that align better with modern usage.

Smart Chargers in Dubai 2026: What Makes a Charger Truly “Smart”?

Understanding Smart Charging Technology

When you search for smart chargers in Dubai 2026, you are looking for more than speed. You are looking for smart features such as intelligent controlled power delivery, heat management, and compatibility with Android and iOS.

USB-C Fast Chargers in Dubai: Speed Without Battery Stress

Modern chargers listed on Ready2Resale and other online sites are focused on wireless charging and USB-C fast charging. A USB-C fast charger Dubai option offers 20W to 30W power levels. So your battery won’t be stressed and your phone will reach charge levels in less than an hour.

Wireless Chargers in Dubai: Everyday Convenience

Convenience is the main advantage of wireless chargers. If you like to keep your desk and nightstand uncluttered, wireless chargers let you simply place your phone on top to start charging. These chargers are especially useful if you often take your phone in your hand and need to put it down to look at your screen.

Why Verified Chargers Matter in Phone Accessories Dubai

In the phone accessories Dubai market, the low priced and verified charging options stand out because of the safety and performance balance. Whereas that often lacks in unverified and cheap chargers.

Some Dubai phone chargers provide a balance of safety and performance, which is why they are sought after.

Affordable Phone Chargers Dubai: Price Without Compromise

USB-C Fast Charger Dubai Price Overview

USB-C fast chargers on Ready2Resale range from AED 45-65. While wireless charging pads range from AED 55-75. These prices are lower than physical retail outlets while still providing modern charging standards.

Why Budget Phone Accessories Dubai Still Need to Protect Your Device

When comparing fast charging USB-C Dubai price options, these chargers are economical options. Because they provide rapid charging capabilities for newer phone models.

This captures the need for budget phone accessories Dubai that do not compromise on device longevity.

Best Earphones Dubai: Sound Quality That Fits Your Life

Why Earphones Control Your Smartphone Experience

Chargers keep your phone alive to function. While earphones control your device experience. Best earphones Dubai are essential, especially for watching videos and listening to music. Quality control is especially important.

Wireless Earphones Dubai and the Shift Toward Cable-Free Audio

By 2026, best earphones Dubai searches will increase for wireless options. Wireless audio is convenient, making wireless earphones Dubai and Bluetooth earphones Dubai the most used options.

Bluetooth Earphones Dubai: Reliable for Work and Calls

Why Neckband Bluetooth Earphones Still Make Sense

Bluetooth neckband earphones are still a good option for business settings. As they have good battery life, stable connectivity, and reliable call quality. And they are good for business settings with multiple calls or meetings.

Affordable Bluetooth Earphones Dubai for Business Users

They are usually priced between AED 55-75 which makes them great business affordable earphones Dubai.

True Wireless Earbuds Dubai: Compact and Modern Audio

Why Wireless Earbuds Dominate the Dubai Market

For an experience that is more compact and modern, Dubai wireless earbuds have dominated the market. These earbuds are great for portability, have a clean design, and better than average quality sound for general use.

Best Earphones Under Budget Dubai for Everyday Use

They are usually priced between AED 80-110 which makes them best earphones under budget Dubai.

Bluetooth vs True Wireless: Choosing the Right Audio for You

When Bluetooth Earphones Are the Better Option

When searching for quality Bluetooth headphones in Dubai, UAE, you may find yourself in a position where true wireless earbuds could be a perfect fit for you at a better price. This all depends completely on how you use your phone.

When True Wireless Earbuds Fit Better

For uninterrupted calls and a longer battery life with less chance of losing an earbud, Bluetooth neckband earphones would be better for you. If you need a lightweight design and portability, then Dubai true wireless earbuds are better.

They are all available under the phone chargers and earphones deals in Dubai which gives you the option to choose based on your lifestyle.

Smart Comparison: Chargers and Earphones Available in Dubai (2026)

| Category | Type | Key Features | Price (AED) |

| Charger | USB-C Fast Charger | Fast, safe, iPhone & Android compatible | 45–65 |

| Charger | Wireless Charger | Cable-free, desk-friendly | 55–75 |

| Audio | Bluetooth Earphones | Clear calls, long battery life | 55–75 |

| Audio | True Wireless Earbuds | Compact, modern, cable-free | 80–110 |

This comparison reflects the most practical choices within the phones accessories Dubai market today.

Why These Phone Accessories Dubai Outperform Typical Market Options

The Risk of Cheap and Unverified Mobile Accessories Dubai

Many mobile accessories Dubai sold through informal channels may appear attractive due to low prices. But they often fail in durability, sound consistency, or charging safety. This is why genuine phone accessories Dubai remain a priority for informed buyers.

Why Online Stores Are Gaining Trust in Dubai

Online platforms that focus on transparency and pricing clarity increasingly outperform traditional retail stores. As a result, shoppers looking for discount phone accessories Dubai online 2026 are shifting toward verified online sellers rather than impulse mall purchases.

How These Phone Accessories Fit Your Daily Routine

Choosing Accessories Based on Real Usage Habits

Think about how often you charge your phone. How many calls you take. How often you move between locations. These small habits define your needs for genuine phone accessories Dubai more than any marketing claim.

Why Phone Accessories Dubai Are No Longer Optional

Thus, from this year, phone accessories Dubai have become essential rather than optional upgrades. As they help to streamline productivity, communication, and convenience. The right wireless charger and earbuds combo Dubai help your phone work for you, rather than against you.

Final Outlook: Smarter Purchases in 2026

If you’re looking for where to buy affordable earphones in Dubai and comparing wireless earbuds deals Dubai 2025-2026, or upgrading your charging setup, you need to be selective.

Optimizing Your Digital Life with the Right Phone Accessories

The best budget phone accessories Dubai for your needs are the ones that defend your device, are reasonably priced, and help improve your usage.

In a connected city like Dubai, selecting phone accessories Dubai is not about trends. Rather it is about simplifying, securing, and optimizing your digital interactions.

FAQs

Which company makes the best phone chargers?

The best phone charger is one that meets modern safety and fast-charging standards, not just one that claims to from a single brand. NO FUSS, NO MESS The certified USB-C rapid chargers and the wireless charging pads offered by reputable online retail stores like Ready2Resale are safe for everyday use in Dubai.

What kind of phone charger do I need in Dubai?

You’ll need something in the region of a USB-C fast charger (20W–30W) for everyday use in Dubai. And possibly a wireless charging pad for your desk or nightstand. Both are great options for city-dwellers in search of a quicker pace.

What is the best quality phone charger?

The top quality phone charger not only has a stable power output but also increases the service life of your battery, provides temperature protection, and awakes you with beautiful music in the morning. Certified USB-C and Qi-certified wireless chargers would satisfy this.

Is a wireless charger worth buying?

Yes, a wireless charger is worth buying if you value convenience. It is ideal for home or office use, reduce the cable mess, and provides a practical solution for long phone calls at work.

Which earphones are best for phone calls?

Bluetooth neckband earphones are best for phone calls due to their stable connectivity, clear microphones, and longer battery life.

Which is the No. 1 earphone brand?

There is no single No. 1 earphone brand. Ultimately, the right option for you depends not on label but usage and comfort coupled with sound reliability.

What are the best noise-cancelling headphones in Dubai?

Noise-cancelling headphones are not the focus of this blog. For daily calls and commuting, Bluetooth earphones and true wireless earbuds provide sufficient noise isolation.

Blogs

Bike Transport Charges Service in India: Economy vs Premium Options

Published

1 month agoon

January 12, 2026By

Steven

Relocating your motorcycle for the first time brings an important decision: should you opt for the affordable open carrier method or invest in premium enclosed transport? This choice significantly impacts both your bike transport charges and the safety of your prized possession during transit. For Indian bike owners aged 25-60, whether you’re transferring a daily commuter like a Honda Activa or a premium Harley-Davidson, understanding the difference between economy and premium options helps you make an informed first-move decision.

Understanding Bike Transport Charges Service: The Basic Framework

The bike transport charges service industry in India operates on two distinct models, each catering to different customer needs and budgets. Open carrier transport, the economy option, involves loading multiple motorcycles onto an open truck bed where they’re secured but exposed to weather and road elements. Enclosed truck transport, the premium alternative, places your bike inside a covered container that shields it from dust, rain, and external damage throughout the journey.

The pricing difference between these options reflects the level of protection and service quality. Open carrier bike transport charges typically range from ₹3,000 to ₹7,000 for distances between 500-1,000 kilometers, while enclosed transport for the same distance can cost ₹6,000 to ₹15,000 depending on your bike’s value and the service provider’s reputation. These figures vary based on factors like fuel prices, route difficulty, and seasonal demand, similar to how car transportation service pricing fluctuates across India.

Economy Option: Open Carrier Bike Transport Charges

Open carrier transport dominates the Indian market because it offers practical, budget-friendly relocation for everyday motorcycles. When you book this service, your bike travels alongside 4-8 other vehicles on a single truck, allowing transport companies to distribute costs among multiple customers. This economy of scale directly translates to lower bike transport charges for you.

The process involves securing your motorcycle with sturdy ropes and chains to prevent movement during transit. Professional handlers ensure proper tie-down techniques that avoid damage to bodywork or mechanical components. For someone relocating a standard commuter bike between Pune and Ahmedabad or Chennai and Coimbatore, open carrier transport provides adequate protection at reasonable prices.

However, this option comes with considerations. Your bike remains exposed to highway dust, potential monsoon rain, and the occasional stone chip. While reputable bike transport charges service providers use protective covers, complete weather shielding isn’t guaranteed. For bikes valued under ₹1.5 lakhs or older models where minor cosmetic exposure doesn’t concern you, open carrier transport makes practical financial sense during your first move.

Premium Option: Enclosed Truck Bike Transport Charges Service

Enclosed transport represents the premium tier of bike transport charges service, offering comprehensive protection that justifies higher costs. Your motorcycle travels inside a fully covered container truck, isolated from weather, dust, and road debris. This method particularly appeals to owners of high-value bikes, vintage motorcycles, or recently purchased premium models where maintaining showroom condition matters.

The enclosed option provides several advantages beyond weather protection:

- Enhanced security: Reduced visibility of transported vehicles deters potential theft during transit stops

- Minimal handling: Fewer loading and unloading procedures compared to shared open carriers

- Climate control possibilities: Some premium services offer temperature-regulated containers for vintage or high-end motorcycles

- Dedicated space: Your bike doesn’t share space with multiple vehicles, reducing contact damage risks

- Insurance coverage: Premium bike transport charges typically include comprehensive insurance as standard

For professionals relocating a Royal Enfield Continental GT, KTM Duke, or imported superbike, the additional investment in enclosed transport protects both the vehicle’s condition and resale value. First-time movers often underestimate how much difference this protection makes, especially on routes like Delhi to Mumbai or Bangalore to Kolkata where weather conditions vary dramatically.

Making the Right Choice for Your Bike Transport Charges

Your decision between economy and premium options should balance multiple factors beyond just the immediate bike transport charges service cost. Consider your motorcycle’s market value first—a general rule suggests enclosed transport for bikes valued above ₹2 lakhs. However, emotional attachment and future plans also matter. If you’re relocating a bike with sentimental value or planning to sell it soon, premium transport preserves its condition and marketability.

Route and season significantly influence this decision. Relocating during monsoon months through regions like Kerala, West Bengal, or the Northeast monsoon-affected areas makes enclosed transport more attractive despite higher bike transport charges. Conversely, winter relocations on well-maintained highways between metros might not require premium protection for standard motorcycles.

Insurance coverage represents another critical consideration. While basic insurance comes standard with most bike transport charges service packages, enclosed transport typically offers higher coverage limits. Review the insurance certificate carefully—ensure it covers the full replacement value of your motorcycle, not just a depreciated amount. This attention to detail proves especially important during first moves when you’re unfamiliar with industry standards.

Comparing Bike Transport Charges: Value Beyond Price

Looking beyond the immediate cost difference reveals the true value proposition of each option. Economy transport suits budget-conscious relocations where minor cosmetic exposure doesn’t concern you. It’s the same principle that makes open carrier car transportation service popular for older vehicles—functionality matters more than pristine appearance.

Premium enclosed transport, while costlier upfront, potentially saves money long-term by preventing repair expenses for weather damage, scratches, or mechanical issues caused by inadequate protection. Calculate these potential costs against the higher bike transport charges service fees. For a ₹3 lakh motorcycle, spending an additional ₹5,000 on enclosed transport makes financial sense compared to potential repair bills of ₹10,000-₹15,000 for fixing weather or transit damage.

Final Considerations for First-Time Bike Transport Charges Service Users

During your first bike relocation experience, prioritize companies offering transparent pricing breakdowns. Reputable providers clearly explain what their bike transport charges include—insurance limits, loading assistance, door-to-door delivery, and GPS tracking availability. Request written quotations comparing both economy and premium options, giving you flexibility to make an informed choice based on your specific situation and budget constraints.

Blogs

Jewellery Auctions That Deliver Trust, Value, and Results

Published

1 month agoon

January 12, 2026By

Steven

Selling or buying jewellery can feel uncertain, especially when value, trust, and transparency are at stake. Many people worry about underpricing, unclear processes, or dealing with the wrong buyers. As a result, valuable pieces often sit unused or are sold without achieving their true worth. However, jewellery auctions offer a clear, professional solution. They bring qualified buyers and sellers together in a structured environment where expertise guides every step. Furthermore, reputable auctioneers remove guesswork by providing accurate valuations and market exposure. With the right auction house, jewellery auctions become a secure and informed way to achieve fair market value while enjoying a smooth, well-managed experience from start to finish.

Understanding Jewellery Auctions and How They Work

Jewellery auctions are organised sales where jewellery is offered to bidders in a competitive setting. Each piece is carefully assessed before being presented to the market. Therefore, buyers gain confidence, while sellers benefit from fair pricing driven by demand.

At a professional auction house, specialists review items for age, condition, and current market appeal. For example, antique rings, vintage bracelets, and signed pieces are grouped and catalogued accurately. As a result, buyers can make informed decisions, and sellers receive realistic expectations. Jewellery auctions follow a clear structure, which helps reduce uncertainty and ensures every item receives appropriate attention.

Why Jewellery Auctions Are Trusted by Buyers and Sellers

Trust is essential when handling valuable items. Jewellery auctions provide this through transparency and expert oversight. Moreover, auction results are publicly recorded, which supports confidence in pricing.

Buyers appreciate access to verified items, while sellers value competitive bidding. However, trust depends on experience and knowledge. Established auctioneers apply strict standards during valuation and presentation. Consequently, jewellery auctions remain a preferred option for individuals, collectors, and estates seeking dependable outcomes.

Types of Jewellery Commonly Sold at Auction

Jewellery auctions cover a wide range of styles and periods. This variety attracts diverse buyers and encourages competitive bidding.

Antique and Period Jewellery

Antique jewellery often includes Georgian, Victorian, and Edwardian pieces. These items are valued for craftsmanship and rarity. Therefore, accurate dating and condition reports are essential.

Vintage and Modern Jewellery

Vintage and modern designs appeal to both collectors and everyday buyers. For instance, mid-century gold jewellery or contemporary diamond pieces often perform well. Jewellery auctions provide exposure to audiences actively seeking these styles.

Signed and Designer Jewellery

Signed pieces from recognised makers command strong interest. As a result, expert verification is crucial. Auction specialists ensure authenticity, which protects both buyers and sellers.

The Valuation Process Behind Successful Jewellery Auctions

Valuation is the foundation of jewellery auctions. Without accurate assessments, results suffer. Therefore, specialists examine materials, gemstones, and craftsmanship carefully.

Market trends also play a role. For example, demand for certain gemstones or periods may rise. Consequently, valuations reflect both intrinsic value and current interest. Jewellery auctions rely on this balanced approach to guide reserve prices and estimates.

How Jewellery Auctions Maximise Market Exposure

One major advantage of jewellery auctions is access to a broad buyer base. Instead of relying on a single buyer, auctions create competition. Moreover, catalogues and previews allow buyers to research items in advance.

Auction houses promote upcoming sales through targeted marketing. As a result, jewellery reaches collectors, dealers, and private buyers simultaneously. This exposure increases the likelihood of achieving strong results. Jewellery auctions thrive on visibility and informed participation.

Selling Jewellery at Auction: What to Expect

Selling through jewellery auctions follows a clear process. First, items are reviewed and valued. Next, sellers receive guidance on estimates and reserves.

Once consigned, jewellery is catalogued and presented professionally. During the sale, bidding determines the final price. Afterward, sellers receive payment promptly, subject to agreed terms. Therefore, jewellery auctions offer a structured and predictable selling experience.

Buying Jewellery at Auction with Confidence

For buyers, jewellery auctions provide access to unique pieces at market-driven prices. However, preparation is important. Reading catalogues and condition reports helps manage expectations.

Viewing days allow buyers to inspect items in person. As a result, informed bidding becomes easier. Jewellery auctions reward research and careful decision-making, which supports positive buying experiences.

Online and In-Person Jewellery Auctions Explained

Modern jewellery auctions operate both online and in person. Each format has benefits. In-person auctions offer atmosphere and immediate feedback. Online auctions, however, provide convenience and wider access. Therefore, buyers and sellers can choose the format that suits them best. Many auction houses now combine both, ensuring jewellery auctions remain accessible and competitive.

The Role of Expertise in Jewellery Auctions

Expertise separates successful jewellery auctions from poor experiences. Specialists understand materials, history, and market behaviour. Consequently, their knowledge protects value and builds confidence.

Professional auctioneers also manage legal and ethical responsibilities. For example, clear ownership checks and transparent terms safeguard all parties. Jewellery auctions depend on this professional framework to maintain credibility.

Jewellery Auctions for Estates and Private Sellers

Jewellery auctions are often used for estate dispersals. They provide an efficient way to handle multiple items fairly. Moreover, private sellers benefit from guidance without pressure.

Auction specialists offer advice on timing and presentation. As a result, jewellery auctions become a practical solution during sensitive situations, ensuring respectful and accurate handling of valuable items.

Choosing the Right Auction House for Jewellery Auctions

Selecting the right auction house matters. Experience, reputation, and clear communication are key factors. Therefore, sellers should seek specialists with proven jewellery knowledge.

Established auctioneers offer realistic estimates and honest advice. Jewellery auctions succeed when expectations align with market conditions. A trusted auction house supports this balance through expertise and transparency.

Conclusion: Why Jewellery Auctions Remain a Smart Choice

Jewellery auctions continue to offer a reliable way to buy and sell valuable items. They combine expert valuation, market exposure, and transparent processes. Furthermore, competitive bidding often achieves fair market value. Whether you are a private seller, collector, or estate executor, jewellery auctions provide structure and confidence. With professional guidance, the process becomes clear and manageable, delivering results that reflect true market demand.

Choose jewellery auctions with Gildings Auctioneers for trusted valuations, competitive bidding, and professional results. Our expertise ensures your jewellery achieves fair market value through secure, transparent jewellery auctions.

Trending

FASHION1 month ago

FASHION1 month agoChromeheart Jeans Winter Sale USA – Shop Authentic Luxury Denim for Less This Season

BUSINESS2 months ago

BUSINESS2 months agoPalm Jebel Ali Villas: Off-Plan Opportunities You Shouldn’t Miss

Blogs2 months ago

Blogs2 months agoOVO Clothing Online Store

TECHNOLOGY2 months ago

TECHNOLOGY2 months agoAI Detector: Redefining Originality in the Age of Infinite Content

HEALTH2 months ago

HEALTH2 months agoHow important is sperm morphology in a semen analysis normal report

EDUCATION2 months ago

EDUCATION2 months agoThe Positive Power of Language Learning in Modern Life

NEWS1 month ago

NEWS1 month agoTime in Mumbai, India: Local Clock, Time Zone, and Planning Tips

BUSINESS2 months ago

BUSINESS2 months agoVinny Pizza: A Flavor Story That Goes Beyond the Slice